Design

- Unlike

traditional Horizontal Vacuum Belt Filters, we do not need expensive

rubber carrier transporter belts, heavy steel support structures,

transporter belt wearing strips, belt tension mechanisms,

reciprocating trays, flexible tray connections, tray support rollers,

geared motors, cloth travel measurement, electrical control panels,

etc.

Materials

of Construction -

The

above is a list of the components that we DO NOT need in our design.

Our filter framework structure and index mechanism is inexpensive

compared to the HVBF. The materials of construction can be anything

which can be fabricated, such as stainless steel or polypropylene. To

index the filter we use either compressed air, or hydraulics. The

filter has no electrical requirement, making it an ideal selection in

flameproof areas. Other than the actual filter cloth, the Polyfilter

has no consumable wearing parts. Mechanical components are guaranteed

for 3 years.

Feeding

and Cake Washing -GENERAL

- Unlike the HVBF which must have a continuous supply of feed slurry

and cake washing liquid, both carefully regulated to the forward

speed of the belt, the filter cloth on the POLYFILTER is stationary,

(just like the laboratory Buchner filter), whilst filtration and cake

washing are taking place. The benefit of this is that the feed can be

applied either continuously, or, if necessary, in small volumes in

synchronisation with the filter index. The same applies to the cake

wash liquid. The actual decision depends upon the characteristics of

the product, not the design of the filter!

Cake

Washing -(1)

- Once the above is understood, it can be seen that the benefits of

plug flow washing can be exploited to full advantage. Since the cake

is stationary. any wash applied above a compartment, or zone, must

exit the filter from that zone, or, if the filter is allowed to

index, the next zone(s) along. This is particularly beneficial on

liquor recovery applications where an excess of wash liquid would

dilute the product. Additionally, by fitting valves or orifice plates

in the manifold headers, the rate of liquor flow from the filter can

be controlled. On fast filtering, open structured crystaline type

products, this ensures a better wash recovery.

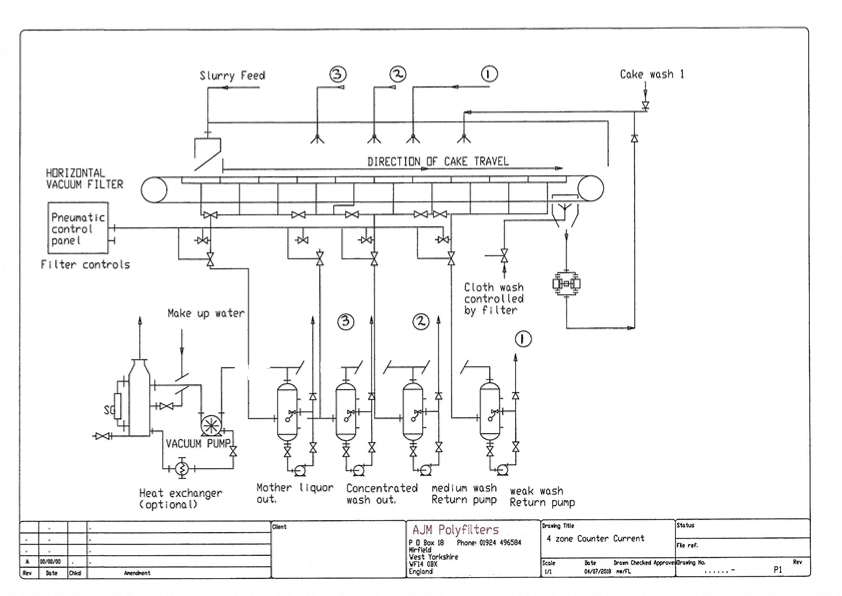

Counter

Current Cake Washing -(2)

- From the above it can be seen that the Polyfilters design is ideal

for this technique of minimising wash liquor consumption. The cut

points are easily identified, and, easily adjusted, without the need

of stopping the filter. Any number of stages can be incorporated.

Cake

Drying

- On the drying end of the filter, it is possible to fit a cake

squeezing plate, which, on some products, can match the cake solids

achieved by membrane plate type filter presses. Alternatively, with

crystalline structured products, hot air tunnels can be incorporated

thus turning the filter into a simple dryer.

Cloth

Washing

- The indexing design of the Polyfilter permits very small quantities

of liquid to be used for cloth washing as the liquid only needs to be

applied as the cloth indexes. If the product is the solid, the cloth

wash liquor can be pumped back onto the filter, thus eliminating

product losses. On cake washing filters, the cloth wash can become

part, or all, of the cake wash.

Other

Applications

- Whilst being a continuous filter, the POLYFILTER vacuum belt filter

can also be used for BATCH processes. Here, its performance

flexibility has seen it out perform more traditional equipment such

as ; basket and decanter centrifuges, nutsche filters, filter presses

and enclosed pressure filters.

Batch

applications include: -

Aluminium Powder, Copper Oxide, Copper Carbonate,

Dental Polymer, PAA, Polyurethane Foam, Guignets Green, Salt